Pocket filters

Filter construction

Pocket-type air filters are manufactured with coarse, medium and fine cleaning (coarse cleaning from G3-G4 class, medium cleaning from M5-M6, fine from F7-F9). For coarse cleaning, bulk materials from 100% polyester are used, for fine cleaning material based on polypropylene using "meltblown" technology.

Filters are manufactured entirely on rolled galvanized steel profiles, without the use of adhesives.

The fastening of the filter pockets in the main frame is carried out reliably due to the seam connection of the inner frame with the upper crimp guide (clip) on a fully automatic line, without human intervention.

Each batch of filter material is tested on the tester ALF 114 (TOPAS, GmbH), in order to confirm the parameters (initial pressure drop, efficiency, etc.), in accordance with GOST R EN 779 - 2014. At the request of the customer, we have a technical the opportunity to conduct testing according to the new European standard ISO 16890.

Welding of pockets is carried out on a specialized ultrasonic line, which guarantees the accuracy of geometric dimensions, reliable connection of seams and, ultimately, the quality of the entire product.

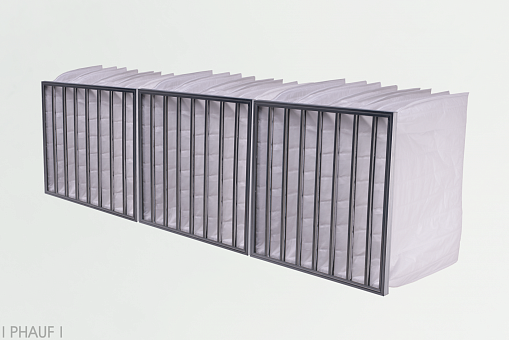

The filter consists of a main frame, internal frames of equal number of pockets, filter pockets (their number depends on the filter size), a seal (optional). The main filter parameters are displayed on the label.

As a sealant, seamless polyurethane foam is used, applied by adhesion on an automated complex DR-CNC (RAMPF, GmbH) or an adhesive-based sealant made of EPDM rubber.

Finished products are packed in a special way in group containers, with all accompanying documents.

Rough pocket filter with polyester material

| Filter type code | Standard size (H x W x D), mm | Number of pockets, pcs. | Cleaning class according to GOST R EN 779-2014 | Nominal productivity, m3/h | Initial pressure drop, Pa | Filtering surface area, м2 | Weight, kg |

| PFPE | 592х287х360 | 6 | G3 | 1700 | 40 | 1,24 | 1,2 |

| 592х592х360 | 3400 | 40 | 2,55 | 1,9 | |||

| 592х592х600 | 1700 | 35 | 2,0 | 1,3 | |||

| 592х592х600 | 3400 | 35 | 4,26 | 2,2 | |||

| 592х287х360 | G4 | 1700 | 45 | 1,24 | 1,2 | ||

| 592х592х360 | 3400 | 45 | 2,55 | 1,9 | |||

| 592х287х600 | 1700 | 40 | 2,0 | 1,3 | |||

| 592х592х600 | 3400 | 40 | 4,26 | 2,2 | |||

| 592х287х360 | M5 | 1700 | 55 | 1,24 | 1,2 | ||

| 592х592х360 | 3400 | 55 | 2,55 | 1,9 | |||

| 592х287х600 | 1700 | 50 | 2,0 | 1,3 | |||

| 592х592х600 | 3400 | 50 | 4,26 | 2,2 |

Fine pocket filter with meltblown material

| Filter type code | Standard size (H x W x D), mm | Number of pockets, pcs. | Cleaning class according to GOST R EN 779-2014 | Nominal productivity, m3/h | Initial pressure drop, Pa | Filtering surface area, м2 | Weight, kg |

| PFPP | 592х287х360 | 8 | M5 | 1700 | 65 | 1,24 | 1,2 |

| 592х592х360 | 3400 | 65 | 2,55 | 1,9 | |||

| 592х287х600 | 1700 | 55 | 2,0 | 1,3 | |||

| 592х592х600 | 3400 | 55 | 4,26 | 2,2 | |||

| 592х287х360 | M6 | 1700 | 80 | 1,24 | 1,2 | ||

| 592х592х360 | 3400 | 80 | 2,55 | 1,9 | |||

| 592х287х600 | 1700 | 70 | 2,0 | 1,3 | |||

| 592х592х600 | 3400 | 70 | 4,26 | 2,2 | |||

| 592х287х360 | F7 | 1700 | 125 | 1,24 | 1,2 | ||

| 592х592х360 | 3400 | 125 | 2,55 | 2,0 | |||

| 592х287х600 | 1700 | 90 | 2,0 | 1,35 | |||

| 592х592х600 | 3400 | 90 | 4,26 | 2,38 | |||

| 592х287х360 | F8 | 1700 | 170 | 1,24 | 1,25 | ||

| 592х592х360 | 3400 | 170 | 2,55 | 2,1 | |||

| 592х287х600 | 1700 | 110 | 2,0 | 1,4 | |||

| 592х592х600 | 3400 | 110 | 4,26 | 2,5 | |||

| 592х287х360 | F9 | 1700 | 220 | 1,24 | 1,28 | ||

| 592х592х360 | 3400 | 220 | 2,55 | 2,1 | |||

| 592х287х600 | 1700 | 160 | 2,0 | 1,45 | |||

| 592х592х600 | 3400 | 160 | 4,26 | 2,6 |

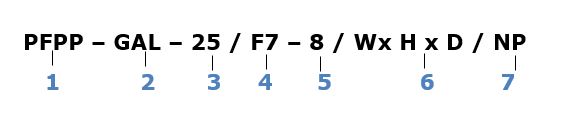

Marking example:

PFPP - GAL – 25 / F7 - 8 / 592 х 592 х 360 / NP

Important!

We produce standard and non-standard filters of different sizes with different number of pockets at the request of the customer.

Pocket filters’ marking

1 Type

PFPE – Pocket filter with polyster filtering material;

PFPP – Pocket filter with polypropylene filtering material;

PFGF – Pocket filter with the filtering material of micro-glass fibre.

2 Design

GAL – Galvanized steel frame;

PLA – Plastic frame

3 Frame thickness (mm).

20; 25; 48.

4 Purity class according to GOST R EN 779-2014

G3; G4; M5; M6; F7; F8; F9.

5 Number of pockets, pcs.

from 3 to 10.

6 Filter dimensions

W – filter width (from 287 to 892 mm);

H – filter height (from 287 to 892 mm);

D – pocket depth (from 100 to 1000 mm)

7 Sealing

NV – continuous sealing on the side of air flow inlet

NP – continuous sealing on the side of air flow outlet

ND – continuous sealing on both sides

Notes to item 1:

*PE – polyester filtering material;

*PP – polypropylene filtering material (meltblown);

*GF – glass fibre filtering material.

Marking example:

PFPP - GAL – 25 / F7 - 8 / 592 х 592 х 360 / NP

Pocket filters – what they are, design specifics

Pocket-type ventilation filters are the devices used for the 1 (first) and 2 (second) stages of air cleaning in plenum exhaust units of ventilation systems for various premises.

Such filters are also used in the air-conditioning and air heating systems of buildings.

Ventilation Pocket Filter Design

The functional elements are made of filtering material welded in the form of several pockets. The number of pockets depends on the filter dimensions.

The larger is the size and the number of pockets, the higher is the capacity and service life of the filtering elements and the lower is the resistance.

Used filtering materials:

- For rough cleaning pocket filters – volume cloths made of 100% polyester (polyester fibre)

- For fine cleaning pocket filters – fibrous cloth material on the basis of polypropylene (Meltblown technology)

The pockets of a fine cleaning filter may be additionally divided into separate sections by a separator. Such segmenting provides for the even distribution of the contaminants captured from the air in the plane of the filtering material.

The filtering element of the product is fastened to the frame with traverses. The latter ensures reliability of the material strain. The number of traverses corresponds to the number of filter pockets.

The filter frame is produced from galvanized steel in the form of a lock on riveted joints or from plastic.

The tightness of attachment of the filtering element to the profile is achieved by foamed sealing laid along the frame parimeter.

Important!

The maximum degree of contamination of the pocket air filters is determined by achieving the final value of pressure drop (measured by differential pressure gauge).

A used filter shall be replaced with a new one – the product is not subject to cleaning, washing or reuse.

Areas of application

Pocket filters are used in medium and high pressure ventilation units, air supply plants of suspended type and floor type.

In one-step air supply plants pocket air filters can be used as the only filtering element for cleaning the outer air from insects, large dust particles and mud.

In multi-step plenum and exhaust ventilation systems of clean premises these devices perform preliminary air processing prior to its feed to the absolute НЕРА filter.

Pocket air filters are also widely used in filter fan equipment of:

- housing premises

- medical centres

- retail space

- production and utility premises

Classification of pocket air filters by air cleaning level

The line of pocket filters by Research and Production MICROSISTEMA LLC is manufactured in compliance with the requirements of updated versions of the international standard EN 779:2012 and national standard GOST R EN 779-2014 and includes the following groups of products:

- Rough air cleaning – filtration classes G3, G4

- Intermediate or medium air cleaning – filtration classes М5 (F5), М6 (F6)

- Fine air cleaning – filtration classes F7, F8, F9

Rough cleaning filters G3, G4

Technical characteristics

Pocket air filters of the first cleaning step perform preliminary (basic) treatment of the intake air in the residential and production premises. They also protect from contamination parts of ventilation units:

- Ventilator nodes

- Heat exchanges of heaters and coolers

- Sections of adiabatic air humidification

- Sections of heat recuperation

Technical characteristics of rough cleaning pocket air filters

| Filter characteristic | Description |

| Product type | Pocket ventilation filter |

| Group | Rough cleaning filters |

| Filtration class according to ЕN 779:2012 | G3, G4 |

| Average effectiveness for the particles of 0.4 μm | less than 40% |

| Average dust holding capacity (particles over 10 μm) Аm, % | G3 80≤Аm<90

G4 90≤Аm |

| Initial resistance | 30 Pa |

| Final resistance (recommended pressure drop) | 250 Pa | Range of working temperatures | From -60 С to +80 С |

| Fire safety (class according to DIN 53438) | F1 |

| Filtering material | Polyester |

Medium and fine cleaning filters М5/F5, М6/F6, F7, F8, F9.

Technical characteristics

Important!

According to the effective GOST R EN 779—2014, the classes of fine cleaning filters F5 and F6 are replaced with medium cleaning classes М5 and М6 with the retention of former characteristics.

The goal of pocket air filters of the 2nd cleaning step is to ensure the established hygienic parameters of air purity inside the buildings.

Fine pocket filters are capable of holding atmospheric contaminants below 1 μm, including allergens and bacteria (class F9). They are suitable for sufficient and effective cleaning of the air in residential, office, medical and similar premises.

They are also used as pre-filters in highly effective HEPA filters in multi-step plenum and exhaust ventilation systems of clean premises and sterile areas.

Technical characteristics of pocket air filters of the second step of cleaning

| Characteristic | Medium cleaning pocket filters | Fine pocket filters |

| Filtration class according to ЕN 779:2012 | М5, М6 | F7, F8, F9 |

| Minimal effectiveness for the particles of 0.4 μm | less than 40% | 35-55-70% |

| Initial resistance | from 70 Pa | from 70 Pa |

| Final pressure drop | 450 Pa | 450 Pa |

| Range of working temperatures | From -60 С to +80 С | From -60 С to +80 С |

| Fire safety (class according to DIN 53438) | F1 | F1 |

| Filtering material | Multi-layer progressive Meltblown | Multi-layer progressive Meltblown |

PFPP designation – GAL – 25 / F7 – 8 / W х H х D / Filters’ NP – definition

The product datasheet, filter information table located on the outer side of the frame profile shall contain the information about the manufacturer, dimensions, purity class and filter productivity by air.

Advantages of pocket air filters

- Simple design

- Low resistance

- High DHC

- Reliable and durable

- Easily replaceable

- Advanced filtering materials (microbiologically inactive, self-extinguishing)

- Utilized as solid construction waste

- Low price

How to choose a pocket air filter

To order and buy a pocket filter for ventilation, it is important to define its form, dimensions, technical characteristics, and required filtration class.

These details are specified in the datasheet of the relevant ventilation unit, in the design documentation of the relevant filter ventilation equipment or on the information table of the “old” (to be replaced) filter.

The specialists of our company will develop and manufacture filters of any design according to the customer’s individual request.

What should you pay attention to when ordering a pocket air filter?

- Frame material – preferably: Galvanized steel rolled section. In some cases quality plastic is allowed

- Pockets material – modern synthetic filtering material (polyester, polypropylene, Meltblown), non-toxic, thermal resistance, multilayer structure, glued with hot melt

- Ensuring complete sealing of all the connections of the construction elements

- It is better to choose rough filter of G3, G4 classes for external air inlets

All the produce of Research and Production Company MICROSISTEMA LLC meets the requirements of Russian national standards (GOST R), technical specifications and fire safety requirements.

Each product is accompanies with a datasheet and quality certificate.