-

Продукция

EPA/HEPA/ULPA фильтры (Серия PHCP)W-образные фильтры (Серия FCW)Бытовые фильтры (СЕРИЯ FPS)Карманные фильтры (СЕРИЯ PF)Кассетные фильтры (СЕРИЯ FKT)Панельные фильтры (СЕРИЯ FPT)Вид:Скачать каталогКласс очистки:Ширина, мм:Высота, мм:Глубина, мм:Площадь фильтрующей поверхности, м²:Номинальная производительность, м³/ч:Фильтрация приточного и вытяжного воздуха необходима для его очистки от макро- и микро- загрязнителей различной природы: песка, пыли, аэрозольных взвесей, запахов, дыма, пара, токсичных газов, инфекционных и радиоактивных частиц, др.Воздушный фильтр простой панельной конструкции представляет собой нарезку фильтрующего полотна, зафиксированного сеткой. Фильтрующий элемент в свою очередь скреплён металлическим профилем П-образной рамы. Панельные фильтры ставят на входе воздушного потока для базовой очистки воздуха от крупных загрязнений.Кассетный фильтр панельной конструкции — это модернизированный панельный фильтр. Фильтр-полотно в кассетном фильтре «смято» в складку (плиссировано) и зафиксировано на гофрированной опорной сетке. Гофрированный фильтровальный элемент помещён в металлическую П-образную или жёсткую прямоугольную раму.Фильтрующий элемент таких конструкций представлен объёмным нетканым материалом, сшитым в виде мешков-карманов, закреплённых в жёсткой раме на поперечных перекладинах. Чем больше количество и глубина карманов, тем больше площадь фильтрующей поверхности и длительней период эксплуатации изделия. В зависимости от типа используемого фильтровального материала, карманные фильтры пригодны для первой и второй ступени очистки воздуха.В компактных фильтрах W-типа плиссированный фильтр-пакет устанавливается в корпус под углом к потоку воздуха в виде W-образных зигзагов. W-форма фильтр-элемента фиксируется армированной сеткой. Сам фильтропакет помещается в лёгкий ударопрочный влагостойкий полимерный корпус. Плиссировка и компактная укладка фильтровального элемента заметно увеличивает эффективную площадь фильтрующего материала. Это повышает пылеёмкость, а значит длительность эксплуатации изделия.Фильтры НЕРА (High Efficiency Particle Absorbption) – это высокоэффективные устройства для окончательной ультратонкой очистки воздуха, прошедшего предварительную (грубую и тонкую) обработку. Механизм улавливания загрязняющих микрочастиц в ХЕПА фильтрах принципиально отличен от других и обусловлен адгезивными свойствами фильтрующего волокна. Кассета НЕРА представляет собой фильтр-пакет из ультратонкой гофрированной сепарированной стеклобумаги герметично вмонтированный в профиль корпуса.Фильтр тонкой очистки с полиуретановым уплотнителем (Серия PHCP), Н14Высокоэффективный фильтр тонкой очистки с полиуретановым уплотнителем, класс очистки Н14, рама 69 ммКласс очистки H14 Ширина, мм: 305 610 610 915 1220 915 1220 1220 Высота, мм: 305 305 610 610 610 915 915 1220 Глубина, мм: 69 69 69 69 69 69 69 69 Площадь фильтрующей

поверхности, м²:3.0 6.1 12.1 18.1 24.2 27.3 36.4 48.4 Номинальная

производительность,

м³/ч:150 300 605 905 1205 1355 1805 2410 Фильтр тонкой очистки с полиуретановым уплотнителем (Серия PHCP), Н13Высокоэффективный фильтр тонкой очистки с полиуретановым уплотнителем, класс очистки Н13, рама 69 ммКласс очистки H13 Ширина, мм: 305 610 610 915 1220 915 1220 1220 Высота, мм: 305 305 610 610 610 915 915 1220 Глубина, мм: 69 69 69 69 69 69 69 69 Площадь фильтрующей

поверхности, м²:3.0 6.1 12.1 18.1 24.2 27.3 36.4 48.4 Номинальная

производительность,

м³/ч:150 300 605 905 1205 1355 1805 2410 Фильтр тонкой очистки с полиуретановым уплотнителем (Серия PHCP), Е12Высокоэффективный фильтр тонкой очистки с полиуретановым уплотнителем, класс очистки Е12, рама 69 ммКласс очистки E12 Ширина, мм: 305 610 610 915 1220 915 1220 1220 Высота, мм: 305 305 610 610 610 915 915 1220 Глубина, мм: 69 69 69 69 69 69 69 69 Площадь фильтрующей

поверхности, м²:3.0 6.1 12.1 18.1 24.2 27.3 36.4 48.4 Номинальная

производительность,

м³/ч:150 300 605 905 1205 1355 1805 2410 Фильтр тонкой очистки с полиуретановым уплотнителем (Серия PHCP), Е11Высокоэффективный фильтр тонкой очистки с полиуретановым уплотнителем, класс очистки Е11, рама 69 ммКласс очистки E11 Ширина, мм: 305 610 610 915 1220 915 1220 1220 Высота, мм: 305 305 610 610 610 915 915 1220 Глубина, мм: 69 69 69 69 69 69 69 69 Площадь фильтрующей

поверхности, м²:3.0 6.1 12.1 18.1 24.2 27.3 36.4 48.4 Номинальная

производительность,

м³/ч:150 300 605 905 1205 1355 1805 2410 Фильтр тонкой очистки с полиуретановым уплотнителем (Серия PHCP), E10Высокоэффективный фильтр тонкой очистки с полиуретановым уплотнителем, класс очистки E10, рама 69 ммКласс очистки E10 Ширина, мм: 305 610 610 915 1220 915 1220 1220 Высота, мм: 305 305 610 610 610 915 915 1220 Глубина, мм: 69 69 69 69 69 69 69 69 Площадь фильтрующей

поверхности, м²:3.0 6.1 12.1 18.1 24.2 27.3 36.4 48.4 Номинальная

производительность,

м³/ч:150 300 605 905 1205 1355 1805 2410 Фильтр тонкой очистки с полиуретановым уплотнителем (Серия PHCP), Н14Высокоэффективный фильтр тонкой очистки с полиуретановым уплотнителем, класс очистки Н14, рама 78 ммКласс очистки H14 Ширина, мм: 305 610 610 915 1220 915 1220 1220 Высота, мм: 305 305 610 610 610 915 915 1220 Глубина, мм: 78 78 78 78 78 78 78 78 Площадь фильтрующей

поверхности, м²:3.0 6.1 12.1 18.1 24.2 27.3 36.4 48.4 Номинальная

производительность,

м³/ч:150 300 605 905 1205 1355 1805 2410 Фильтр тонкой очистки с полиуретановым уплотнителем (Серия PHCP), Н13Высокоэффективный фильтр тонкой очистки с полиуретановым уплотнителем, класс очистки Н13, рама 78 ммКласс очистки H13 Ширина, мм: 305 610 610 915 1220 915 1220 1220 Высота, мм: 305 305 610 610 610 915 915 1220 Глубина, мм: 78 78 78 78 78 78 78 78 Площадь фильтрующей

поверхности, м²:3.0 6.1 12.1 18.1 24.2 27.3 36.4 48.4 Номинальная

производительность,

м³/ч:150 300 605 905 1205 1355 1805 2410 Фильтр тонкой очистки с полиуретановым уплотнителем (Серия PHCP), E12Высокоэффективный фильтр тонкой очистки с полиуретановым уплотнителем, класс очистки E12, рама 78 ммКласс очистки E12 Ширина, мм: 305 610 610 915 1220 915 1220 1220 Высота, мм: 305 305 610 610 610 915 915 1220 Глубина, мм: 78 78 78 78 78 78 78 78 Площадь фильтрующей

поверхности, м²:3.0 6.1 12.1 18.1 24.2 27.3 36.4 48.4 Номинальная

производительность,

м³/ч:150 300 605 905 1205 1355 1805 2410 Фильтр тонкой очистки с полиуретановым уплотнителем (Серия PHCP), E11Высокоэффективный фильтр тонкой очистки с полиуретановым уплотнителем, класс очистки E11, рама 78 ммКласс очистки E11 Ширина, мм: 305 610 610 915 1220 915 1220 1220 Высота, мм: 305 305 610 610 610 915 915 1220 Глубина, мм: 78 78 78 78 78 78 78 78 Площадь фильтрующей

поверхности, м²:3.0 6.1 12.1 18.1 24.2 27.3 36.4 48.4 Номинальная

производительность,

м³/ч:150 300 605 905 1205 1355 1805 2410 Фильтр тонкой очистки с полиуретановым уплотнителем (Серия PHCP), E10Высокоэффективный фильтр тонкой очистки с полиуретановым уплотнителем, класс очистки E10, рама 78 ммКласс очистки E10 Ширина, мм: 305 610 610 915 1220 915 1220 1220 Высота, мм: 305 305 610 610 610 915 915 1220 Глубина, мм: 78 78 78 78 78 78 78 78 Площадь фильтрующей

поверхности, м²:3.0 6.1 12.1 18.1 24.2 27.3 36.4 48.4 Номинальная

производительность,

м³/ч:150 300 605 905 1205 1355 1805 2410 Фильтр тонкой очистки c гелевым уплотнителем (Серия PHCP), U16Высокоэффективный фильтр тонкой очистки с гелевым уплотнителем, класс очистки U16, рама 90 ммКласс очистки U16 Ширина, мм: 305 610 610 915 1220 915 1220 1220 Высота, мм: 305 305 610 610 610 915 915 1220 Глубина, мм: 90 90 90 90 90 90 90 90 Площадь фильтрующей

поверхности, м²:3.0 6.1 12.1 18.1 24.2 27.3 36.4 48.4 Номинальная

производительность,

м³/ч:150 300 605 905 1205 1355 1805 2410 Показать всеФильтр тонкой очистки c гелевым уплотнителем (Серия PHCP), U15Высокоэффективный фильтр тонкой очистки с гелевым уплотнителем, класс очистки U15, рама 90 ммКласс очистки U15 Ширина, мм: 305 610 610 915 1220 915 1220 1220 Высота, мм: 305 305 610 610 610 915 915 1220 Глубина, мм: 90 90 90 90 90 90 90 90 Площадь фильтрующей

поверхности, м²:3.0 6.1 12.1 18.1 24.2 27.3 36.4 48.4 Номинальная

производительность,

м³/ч:150 300 605 905 1205 1355 1805 2410

ФОРМА ЗАКАЗА

ИНФОРМАЦИЯ

Воздушные фильтры – неотъемлемый функциональный элемент систем бытового и промышленного вентиляционно-вытяжного оборудования. Фильтрация приточного и вытяжного воздуха необходима для его очистки от макро- и микро- загрязнителей различной природы: песка, пыли, аэрозольных взвесей, запахов, дыма, пара, токсичных газов, инфекционных и радиоактивныхчастиц, др.

Воздушные фильтры для систем вентиляции торговой марки PHAUF производятся отечественной компанией ООО «НПП «МИКРОСИСТЕМА».

Фильтры PHAUF – это:

- создание оптимально-комфортного микроклимата для людей и производственных процессов в бытовых и промышленных средах;

- защита от загрязнений, износа и повреждений самих воздуховодов, функциональных узлов систем вентиляции, кондиционирования и воздушного отопления;

- очистка от тех или иных промышленных загрязнителей вытяжного воздуха рабочих зон в рамках обеспечения экологической безопасности конкретного производства;

- поддержание установленных международными и национальными стандартами гигиенических требований (классов ИСО чистоты воздуха) в особых рабочих зонах – чистых помещениях и связанных с ними контролируемых средах.

Качество исполнения продукции PHAUF отвечает строгим требованиям европейского стандарта EN 779:2012. Наша компания предлагает самые популярные конструкции фильтров различных классов очистки для

вентиляционных систем. Краткое знакомство с их устройством и назначением поможет Вам сделать правильный выбор.

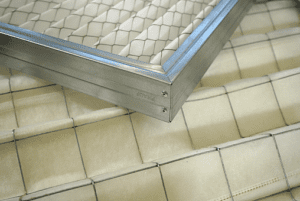

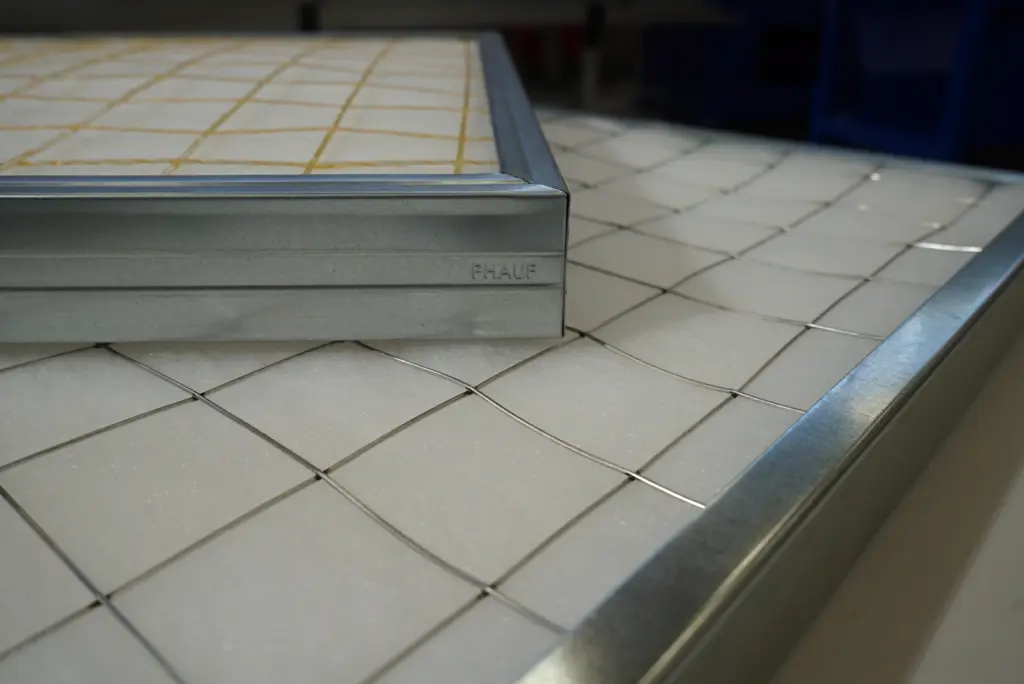

Панельные фильтры

Воздушный фильтр простой панельной конструкции представляет собой нарезку фильтрующего полотна, зафиксированного сеткой. Фильтрующий элемент в свою очередь скреплён металлическим профилем П-образной рамы.

Панельные фильтры ставят на входе воздушного потока для базовой очистки воздуха от крупных загрязнений:

- крупнодисперсной пыли, грязи, песка

- летающих насекомых

- листвы, перьев, шерсти и т. п

Преимущества панельных фильтров:

- высокая прочность;

- простота конструкции;

- низкое начальное аэродинамическое сопротивление;

- съёмный фильтрующий элемент – для регенерации фильтра отработанное фильтр-полотно снимается и заменяется новым;

- низкая стоимость изделия.

Применяются для базовой (грубой) очистки воздуха жилых, общественных и производственных помещений:

- в приточных вентиляционных установках;

- в осушителях;

- специальные панельные фильтры могут применятся в аспирационных установках покрасочных камер.

Классы фильтрации: G2, G3, G4, М5.

Подлежат регенерации.

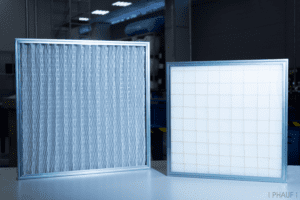

Кассетные фильтры

Кассетный фильтр панельной конструкции — это модернизированный панельный фильтр.

Фильтр-полотно в кассетном фильтре «смято» в складку (плиссировано) и зафиксировано на гофрированной опорной сетке.

Гофрированный фильтровальный элемент помещён в металлическую П-образную или жёсткую прямоугольную раму.

В зависимости от характера фильтрующего материала, кассетные фильтры могут применяться как для грубой, так и для средней очистки воздуха на первой и второй ступенях фильтрации приточно-вытяжного потока.

Входят в комплектацию промышленных и бытовых вентиляционных агрегатов любого типа.

Классы фильтрации: G2, G3, G4, М5.

Подлежат регенерации в зависимости от модели.

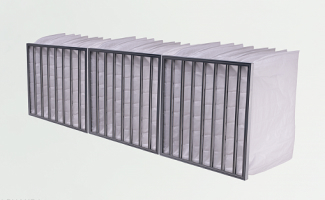

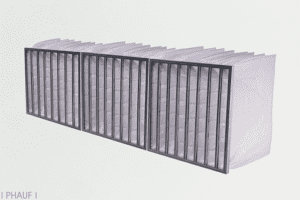

Карманные фильтры

Фильтрующий элемент таких конструкций представлен объёмным нетканым материалом, сшитым в виде мешков-карманов, закреплённых в жёсткой раме на поперечных перекладинах.

Чем больше количество и глубина карманов, тем больше площадь фильтрующей поверхности и длительней период эксплуатации изделия.

В зависимости от типа используемого фильтровального материала, карманные фильтры пригодны для первой и второй ступени очистки воздуха.

Применяются во всевозможных бытовых и промышленных приточно-вытяжных вентиляционных системах зданий и производственных сооружений.

Классы фильтрации: G3, G4, М5, М6, F7, F8, F9.

Регенерации НЕ подлежат.

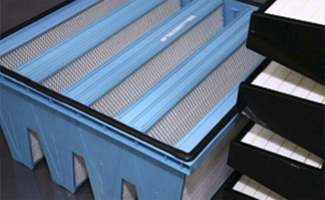

Компактные W-образные фильтры

В компактных фильтрах W-типа плиссированный фильтр-пакет устанавливается в корпус под углом к потоку воздуха в виде W-образных зигзагов.

W-форма фильтр-элемента фиксируется армированной сеткой. Сам фильтропакет помещается в лёгкий ударопрочный влагостойкий полимерный корпус.

Плиссировка и компактная укладка фильтровального элемента заметно увеличивает эффективную площадь фильтрующего материала. Это повышает пылеёмкость, а значит длительность эксплуатации изделия.

W-образные компактные фильтры предназначены для средней и тонкой очистки воздуха. Они улавливают мелкодисперсные и аэрозольные загрязняющие частицы. Служат второй-третьей ступенью фильтрации воздушного потока, прошедшего предварительную грубую очистку.

Чаще всего компактные фильтры используют:

- в промышленных многоступенчатых приточно-вытяжных системах вентиляции и кондиционирования;

- в газотурбинных и компрессорных установках;

- в качестве предфильтров для абсолютных фильтров НЕРА.

Классы фильтрации: М5, М6, F7, F8, F9.

Регенерации НЕ подлежат.

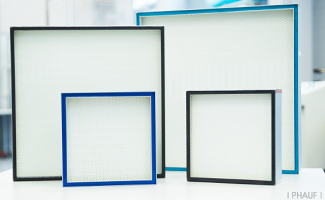

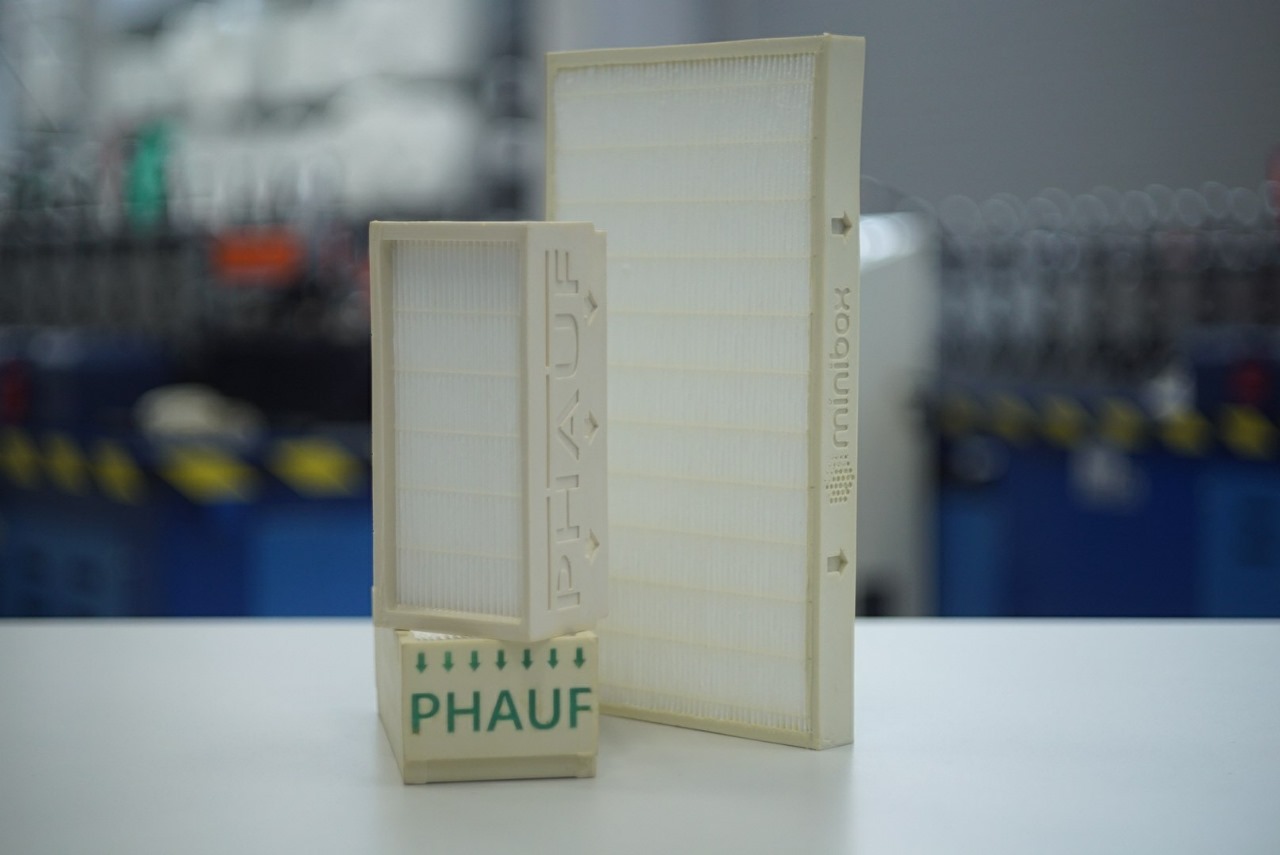

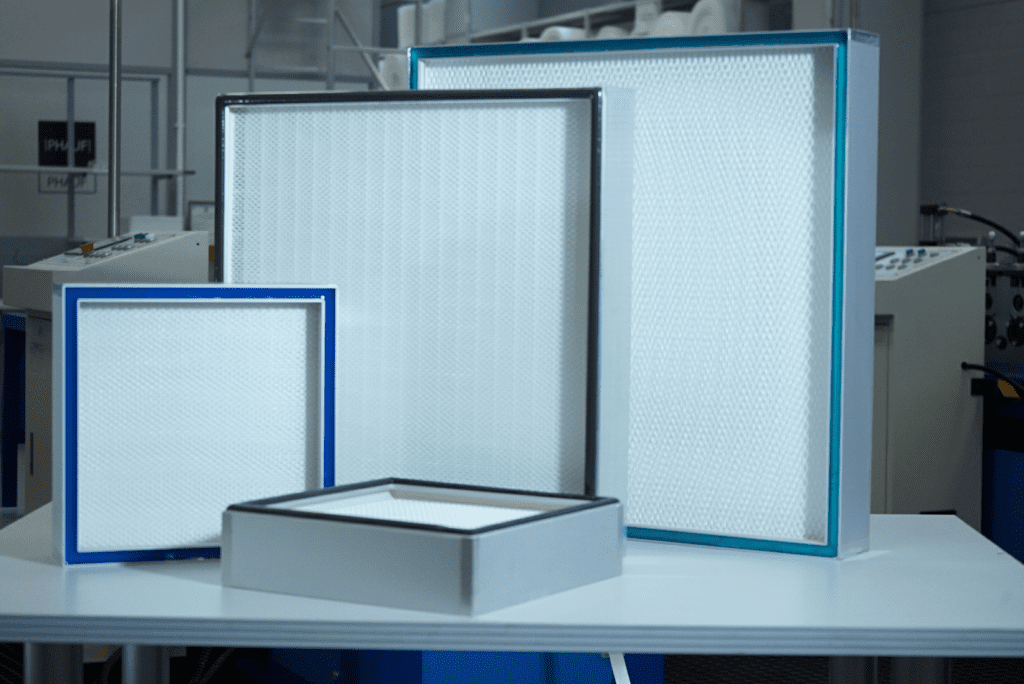

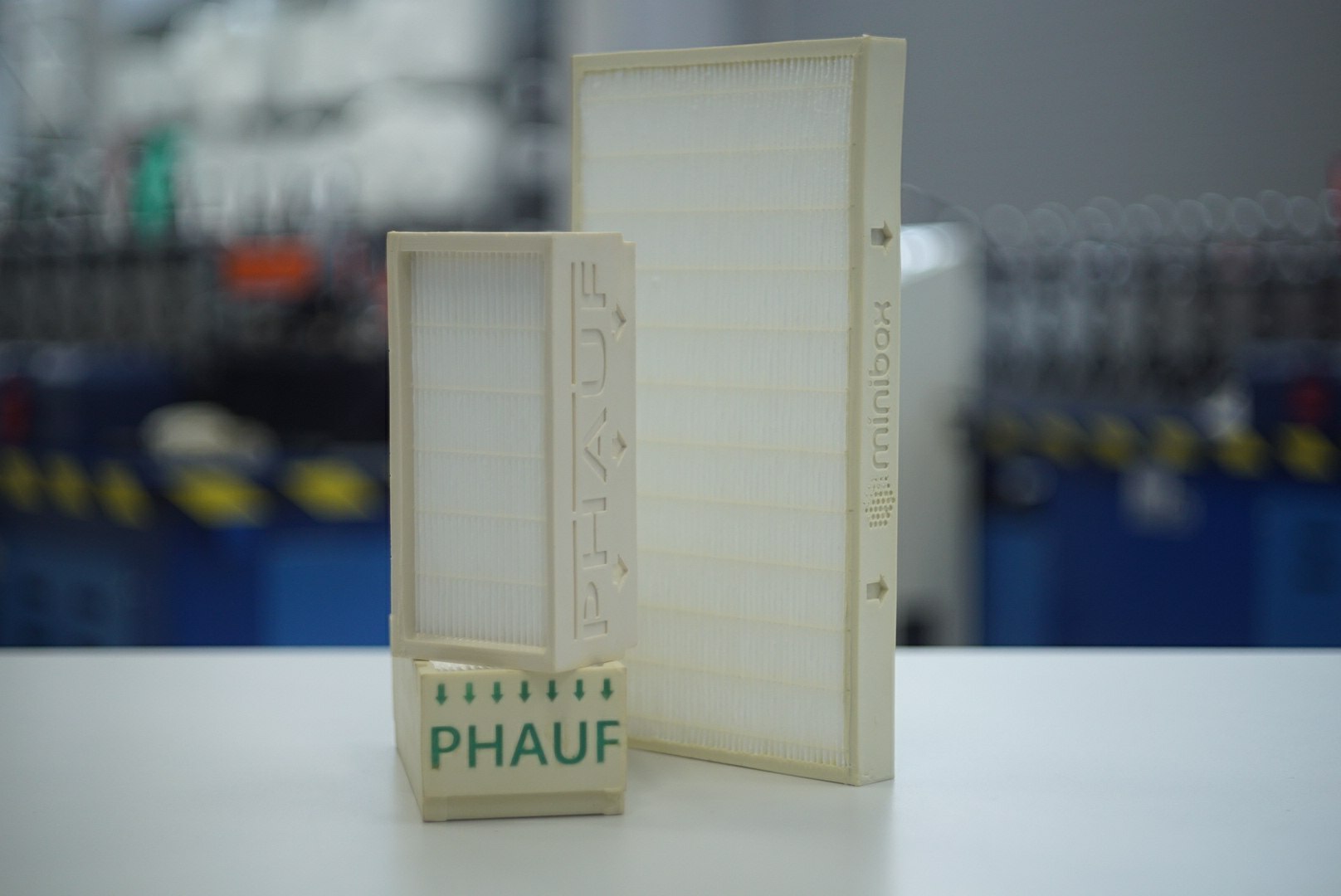

Высокоэффективные НЕРА фильтры

Фильтры НЕРА (High Efficiency Particle Absorbption) – это высокоэффективные устройства для окончательной ультратонкой очистки воздуха, прошедшего предварительную (грубую и тонкую) обработку.

Механизм улавливания загрязняющих микрочастиц в ХЕПА фильтрах принципиально отличен от других и обусловлен адгезивными свойствами фильтрующего волокна.

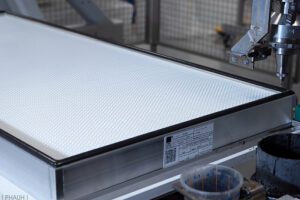

Кассета НЕРА представляет собой фильтр-пакет из ультратонкой гофрированной сепарированной стеклобумаги герметично вмонтированный в профиль корпуса.

Высокоэффективные фильтры осуществляют «стерилизацию» воздуха чистых помещений с установленными классами чистоты ИСО (ГОСТ ISO 14644-1-2002), обеспечивая высочайшие санитарно-гигиенические требования к внутреннему пространству особых зон и рабочих помещений для высокоточной техники.

НЕРА предназначены для финишной очистки воздуха от микро аэрозольных загрязнителей различной природы, бактерий, вирусов, прочих микроорганизмов, радио- и наночастиц.

«Цена» абсолютной очистки – довольно высокое аэродинамическое сопротивление фильтра. Их применение в бытовых вентиляционных установках не всегда целесообразно.

Семейство абсолютных фильтров собственного производства компании ООО «НПП «МИКРОСИСТЕМА» включает изделия классов: EPA, HEPA и ULPA.

Постоянные заказчики продукции НЕРА марки PHAUF:

- медицинские учреждения;

- предприятия пищевой промышленности;

- научно-исследовательские и клинические лаборатории;

- предприятия фармацевтики, радио- и микроэлектроники, оптики, атомной энергетики и др.

Классы фильтрации: Е10, Е11, Е12, Н13, Н14, U15, U16.

Регенерации НЕ подлежат.

Классы фильтров по степени очистки воздуха

В соответствии с обновлённым европейским стандартом (национальный аналог ГОСТ Р ЕН 779-2014) по своей эффективности воздушные фильтры разделяются на три основные группы:

- фильтры предварительной (грубой) очистки воздуха — классы фильтрации G1-G4;

- фильтры промежуточной (средней) и тонкой очистки воздуха — классы М5-М6 и F7-F9 соответственно;

- фильтры абсолютной очистки — классы Е/Н/U-10-17.

| Класс фильтра | Степень очистки |

| G1 | Грубая |

| G2 | Грубая |

| G3 | Грубая |

| G4 | Грубая |

| М5 (F5*) | Средняя |

| М6 (F6) | Средняя |

| F7 | Тонкая |

| F8 | Тонкая |

| F9 | Тонкая |

| Е10 (Н10*) | Высокоэффективная |

| Е11 (Н11) | Высокоэффективная |

| Е12 (Н12) | Высокоэффективная |

| Н13 | Высокоэффективная |

| Н14 | Высокоэффективная |

| U15 | Сверхвысокоэффективная |

| U16 | Сверхвысокоэффективная |

| U17 | Сверхвысокоэффективная |

*- «старое» обозначение класса фильтра без изменения технических характеристик.

Фильтры грубой очистки

Под грубой очисткой подразумевается улавливание из воздушного потока загрязнителей размером более 10 мкм.

Воздушные фильтры грубой очистки для систем вентиляции (классы G2-G4):

- панельные: FPT (ФВФ (ФяП), ФВП);

- кассетные: FKT (ФВКас (ФяГ));

- карманные: PFPE/PFPP/PFGF (ФВК (ФяК)).

Фильтры средней и тонкой очистки

Под средней очисткой подразумевается улавливание из воздушного потока загрязняющих частиц размером более 5 мкм.

Воздушные фильтры средней очистки для систем вентиляции (классы М5-М6):

- карманные: PFPE/PFPP/PFGF (ФВК (ФяК), ФВКуг (угольный));

- компактные W-типа: FCW (PLA) (ФВКом-W);

- кассетные: FKT (ФВКас (ФяГ)).

Под тонкой очисткой подразумевается улавливание из воздушного потока загрязняющих частиц размером более 1 мкм.

Воздушные фильтры тонкой очистки для систем вентиляции (классы F7- F9):

- карманные: PFPE/PFPP/PFGF (ФВК (ФяК), ФВКуг (угольный));

- компактные W-типа: FCW (PLA, PLA-GT) (ФВКом-W, ФВКомУг-W (угольный)).

Высокоэффективные фильтры EPA/HEPA

Под высокоэффективной (абсолютной) очисткой подразумевается улавливание из подаваемого на фильтр воздушного потока взвешенных частиц размером менее 1 микрона (мкм).

Абсолютные фильтры EPA (классы Е10-Е12). удерживают от 85% до 95% таких загрязнителей.

Эффективность фильтров НЕРА (класс Н13-Н14) исчисляется количеством проскочивших через фильтр наноразмерных частиц диаметром 0,1-0,3 мкм и составляет 99,995%.

Фильтры воздушные абсолютной очистки (классы Е10-Е12-Н13-Н14-U15-U17):

- PHCP (ФВА-2) с клеевым сепаратором;

- абсолютный высокой производительности W-типа: FCW (ФВА-НС).

Фильтры сверхвысокой очистки ULPA

Воздух, прошедший сверхвысокоэффективную очистку фильтрами ULPA (класс U15-U17) практически стерилен.

Локальное значение проскока наноразмерных частиц сквозь фильтрующий элемент ≤0,0001%. Степень очистки воздуха достигает 99,999995% и более.

Наглядный пример использования фильтров ULPA – стерилизация воздуха чистых помещений фармацевтических производств, сертифицированных по международному стандарту GMP. Местный персонал работает в специальной технологической одежде (стерильных комбинезонах и бахилах), чтобы «не испачкать» воздух, обработанный абсолютными ULPA.

Виды фильтрующих материалов

Эффективность воздушного фильтра той или иной конструкции во многом зависит от марки используемого в нём фильтрующего материала.

Общие характеристики таких фильтр-материалов:

- нетканая тонковолокнистая или пористая структура;

- класс пожаробезопасности F1 по DIN 53438;

- влагостойкость (способность эффективно работать при высокой влажности воздуха);

- термостойкость (способность эффективно работать при очень низких и очень высоких температурах воздуха);

- экологичность.

Химическое волокно, полиэстер 100%

Под термином «100-процентный полиэстер» подразумевается широкий ассортимент всевозможных марок химических (синтетических) фильтровальных материалов из высококачественного полиэфирного волокна (синтепон, полиэфир, полиэстер, лавсан, ПЭТ).

Предназначен для различных конструкций воздушных фильтров грубой и средней очистки классов G2-М6.

Meltblown

Полимерный объёмный нетканый материал на основе ультратонких полипропиленовых волокон толщиной 1-5 микрон.

Сохраняет хорошую воздухопроницаемость и отличные фильтрационные свойства даже при 100-процентной относительной влажности воздуха.

Применяется для изготовления карманных воздушных фильтров средней и тонкой очистки классов М6-F9.

Комбинированный фильтрующий материал SMS

Многокомпонентный фильтрующий материал SMS представляет собой трёхслойную композицию, спаянную при помощи ультразвуковой сварки продольными и поперечными швами. Слипание карманов предотвращается продольными разделителями.

Структура комбинированного фильтр-полотна SMS марки PНAUF:

- 1-й слой – окрашенный Spanbond для улавливания мелких загрязняющих взвесей (тонкая очистка);

- 2-й слой – электростатически заряженный Meltblown;

- 3-й слой (предфильтр) – бесцветный Spanbond из полиэстера для улавливания крупных частиц (грубая очистка).

Материал SMS используется в воздушных карманных фильтрах тонкой очистки классов М5-F9.

Стекловолокно Paint Stop

Это фильтрующее стекловолокно формируется из тонких стеклянных нитей, уложенных характерной слоистой структурой (каждый слой смещён относительно другого).

Материал предназначен для первой ступени очистки воздуха в сильно запылённых средах и улавливания жидких аэрозольных частиц (например, в покрасочных камерах).

Применяется в панельных фильтрах грубой очистки классов G3-G4.

Стеклобумага

Стеклобумага формируется из более тонких по сравнению со стекловолокном комбинированных нитей.

Материал не впитывает влагу и не теряет своих фильтрующих способностей в средах с высокой влажностью воздуха.

Применяется в компактных воздушных фильтрах тонкой очистки классов F7- F9.

Стеклобумага с угольной крошкой используется в угольных фильтрах тонкой очистки, улавливающих микро-аэрозольные загрязнители и запахи.

Бумага из ультратонкого стекловолокна PНAUF

Для производства фильтр-пакетов абсолютных НЕРА используется специальная фильтровальная стеклобумага, сформированная из хаотично расположенных и плотно уложенных ультратонких нановолокон размером 0,7-6,5 микрон.

Кратность замены воздушных фильтров для вентиляции

Определить индивидуальное время замены для любого воздушного фильтра можно двумя способами.

Способ №1

По сопротивлению фильтра.

Измерить перепад давления на входе и выходе воздушного потока можно с помощью датчиков давления, установленных по обе стороны фильтра, или дифференциальным манометром (дифманометром).

Плановую смену фильтра производят по достижению значений рекомендованного конечного перепада давления.

Способ №2

По времени отработки фильтра, установленного производителем.

В бытовых многоступенчатых фильтровентиляционных приточно-вытяжных системах первым загрязняется фильтр первой ступени очистки наружного воздуха (G3-G4). Штатно его рекомендуется менять один раз в 3 месяца.

Фильтр второй ступени класса М5-F7 меняется в среднем с интервалом от полугода до года в зависимости от степени запылённости наружного воздуха. Подобный вытяжной фильтр «из дома» достаточно заменить один раз в год.

Срок эксплуатации фильтров тонкой очистки класса F9 как правило не превышает одного квартала (3 месяца).

Регенерация фильтров после их эксплуатации

Ни один воздушный тканевый или стекловолоконный фильтр нельзя мыть, стирать, пылесосить. Ворсистая структура фильтровального материала после подобной «чистки» слипается и теряет свои фильтрующие свойства. К тому же удержанные загрязнители из толщи фильтр-материала не вымываются.

Отработанные фильтры систем вентиляции и кондиционирования следует просто заменять на новые, благо стоят они дёшево.

Панельные и кассетные фильтры G2-G4 с П-образным профилем по желанию потребителя могут быть регенерированы путём замены загрязнённого фильтрующего полотна опять же на новое, соответствующего класса фильтрации — самостоятельно или с привлечением специалиста.

Почему клиенты выбирают фильтры марки PHAUF

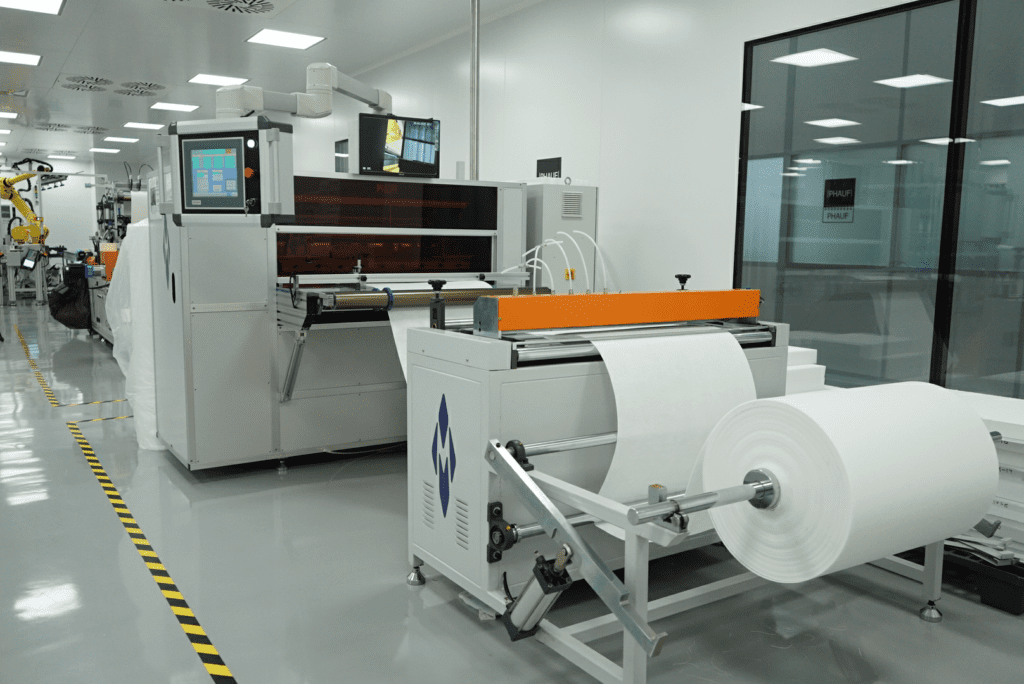

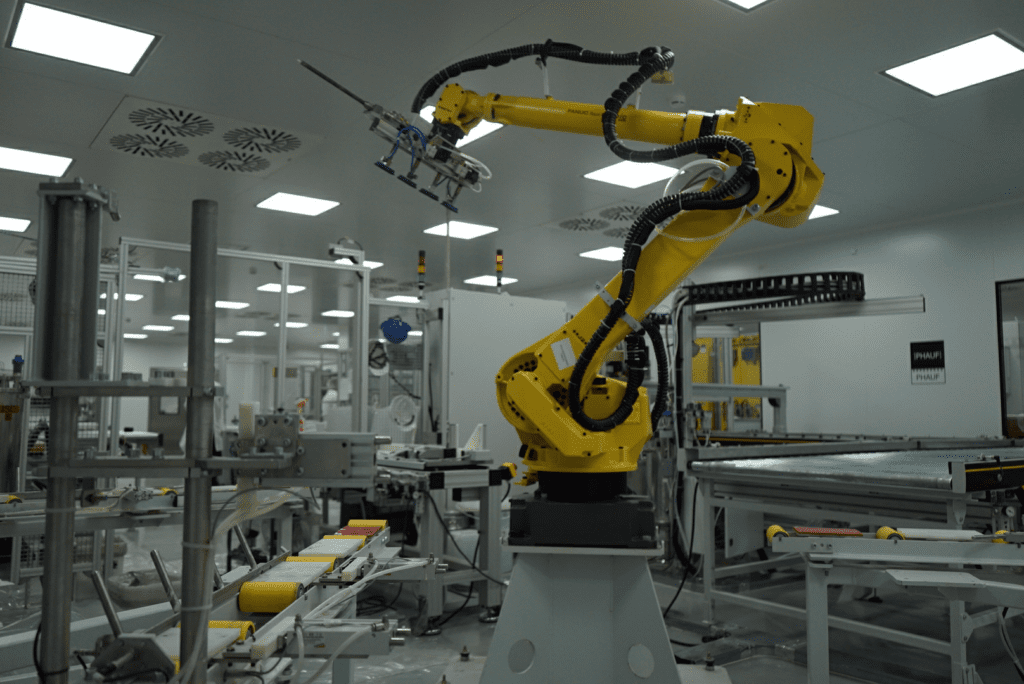

- Производство PHAUF соответствует новейшим мировым тенденциям. Для изготовления фильтров используются современные высокотехнологичные материалы.

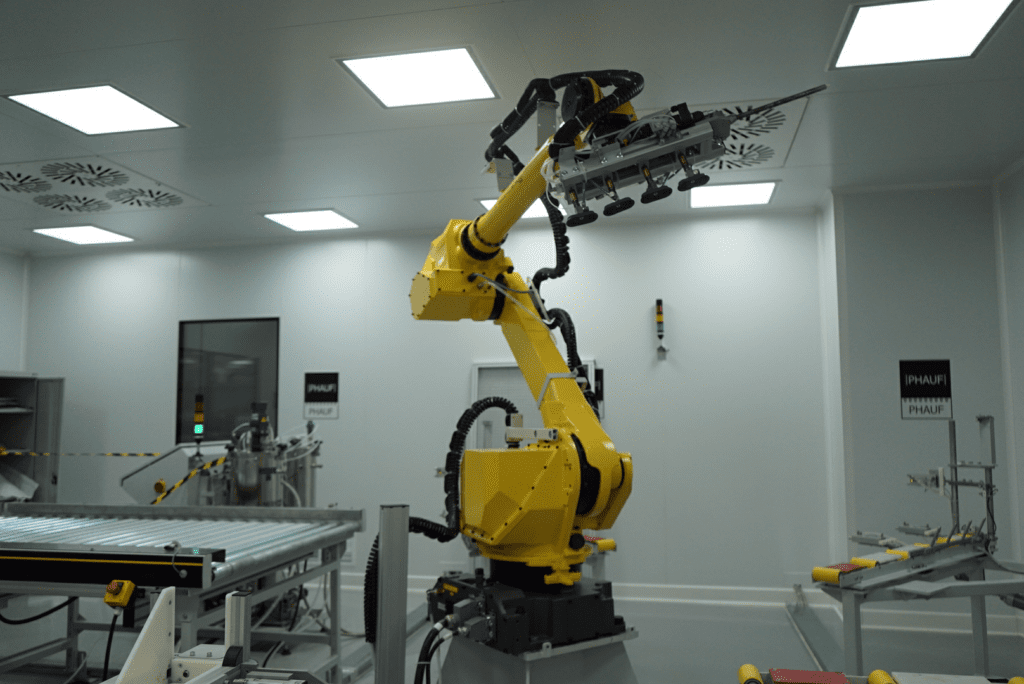

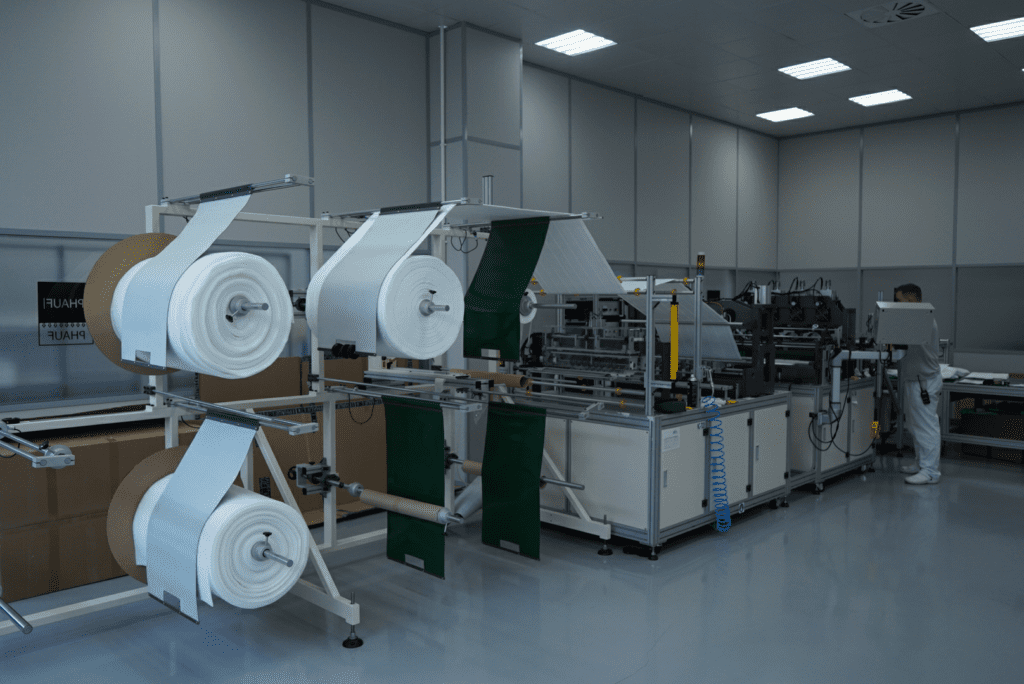

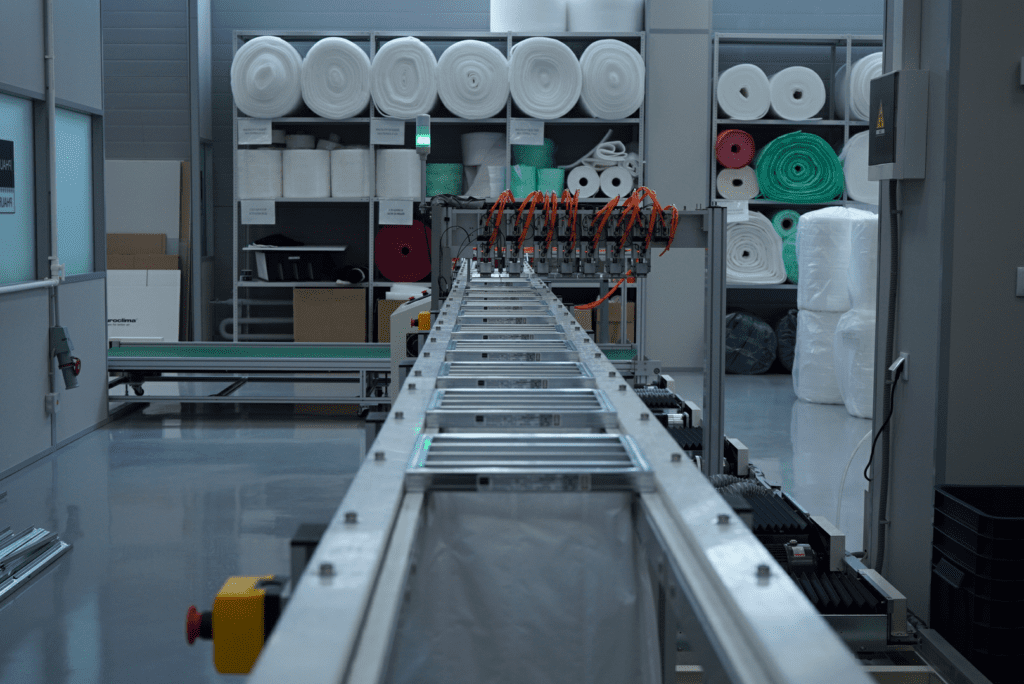

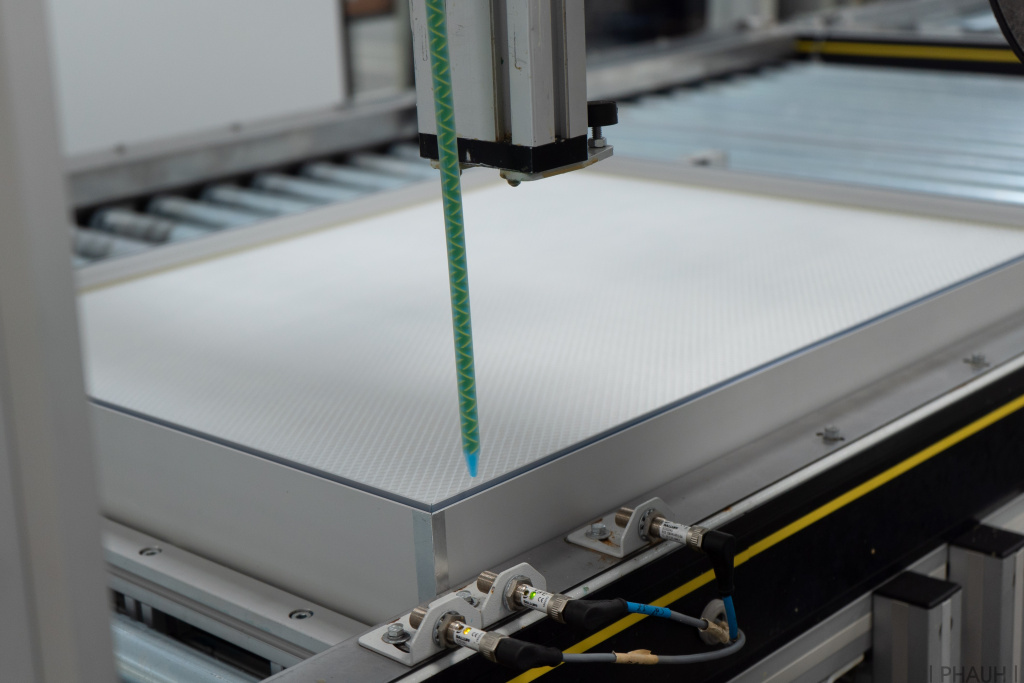

- Фильтры PHAUF производятся в соответствии с технологией «нулевого выброса», включающей в себя: автоматизированную сборку и индивидуальную вакуумную упаковку в чистом помещении класса ИСО7, а также контроль качества каждой единицы продукции на автоматическом сканере TOPAS.

- Производство и индивидуальная вакуумная упаковка абсолютных фильтров HEPA и ULPA осуществляется в чистых помещениях класса ISO-7.

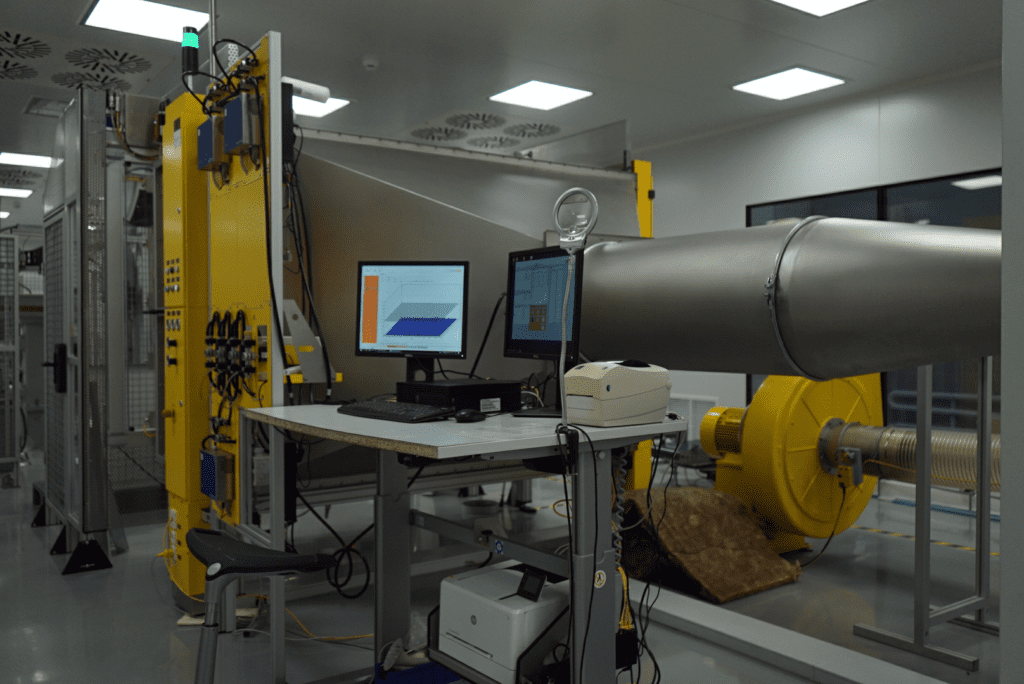

- Каждая единица выпускаемых фильтров PHAUF проходит контроль качества на тест-системах AFS-150 и ALF-114 (TOPAS GmbH, Германия).

- Каждая единица приобретаемой продукции PHAUF сопровождается сертификатом качества, тех. паспортом.

- Технические специалисты PHAUF разрабатывают любые нестандартные воздушные фильтры индивидуальной конструкции по требованию заказчика.

- Производство PHAUF относится к территории Особой экономической зоны технико-внедренческого типа «ИСТОК». Благодаря налоговым и прочим преференциям, у нас Вы можете купить воздушные фильтры для систем вентиляции европейского качества по самой привлекательной цене.