Panel Filters

Filter construction

The filter housing is made of a galvanized profile (standard profile depth 25, 48, 96, 100 mm), on an automated molding line without human intervention, with the possibility of changing the frame depth from 20 to 100 mm, and has a special design to increase the rigidity of the filter frame.

Filtering material made of chemical fiber or glass fiber of cleaning class from G2 to M5, supporting welded meshes with a cell of 50x50 mm made of galvanized or composite rod.

Panel type filter with polyester material

| Frame material / code | Standard dimensions (H x W x D), mm | Purity class GOST R EN 779-2014 | Nominal productivity, m3/h | Initial pressure drop, Pa | Filtering surface area, m2 | Weight, kg |

|

1) Galvanized frame / FGPE 2) Plastic frame / FPPE 3) Stainless steel frame / FSPE |

592х287х25 | G3 | 1700 | 80 | 0,17 | 0,6 |

| 592х592х25 | 3400 | 0,35 | 1,0 | |||

| 592х287х48 | 1700 | 0,17 | 0,8 | |||

| 592х592х48 | 3400 | 0,35 | 1,4 | |||

| 592х287х25 | G4 | 1700 | 100 | 0,17 | 0,6 | |

| 592х592х25 | 3400 | 0,35 | 1,0 | |||

| 592х287х48 | 1700 | 0,17 | 0,8 | |||

| 592х592х48 | 3400 | 0,35 | 1,4 | |||

| 592х287х25 | M5 | 1700 | 120 | 0,17 | 0,6 | |

| 592х592х25 | 3400 | 0,35 | 1,0 | |||

| 592х287х48 | 1700 | 0,17 | 0,8 | |||

| 592х592х48 | 3400 | 0,35 | 1,4 |

Panel-type filter with glass fibre material

| Frame material / code | Standard dimensions (H x W x D), mm | Purity class GOST R EN 779-2014 | Nominal productivity, m3/h | Initial pressure drop, Pa | Filtering surface area, m2 | Weight, kg |

|

1) Galvanized frame / FGGF 2) Plastic frame / FPGF 3) Stainless steel frame / FSGF |

592х287х25 | G3 | 1700 | 70 | 0,17 | 0,6 |

| 592х592х25 | 3400 | 0,35 | 1,0 | |||

| 592х287х48 | 1700 | 0,17 | 0,8 | |||

| 592х592х48 | 3400 | 0,35 | 1,4 | |||

| 592х287х25 | G4 | 1700 | 85 | 0,17 | 0,6 | |

| 592х592х25 | 3400 | 0,35 | 1,0 | |||

| 592х287х48 | 1700 | 0,17 | 0,8 | |||

| 592х592х48 | 3400 | 0,35 | 1,4 |

- Range of operating temperatures: from -40 С to +80 С

- Fire safety class (according to DIN 53438): F1

- Thickness of a filter package (filter depth, thickness of the framework profile) depends on the chosen dimensions of a given product: 15 mm, 25 mm, 48 mm, 96 mm, 100 mm

The technical characteristics of a certain panel filter may differ depending on its modification and manufacturer, for example

Marking example:

FPT – FGPE / G4 -400 / 592 х 592 х 48 / RD

FKT – FGGF / G3 -200 / 592 х 592 х 48 / RD

Designation of PAF filters - definition

The packaging box and the outer side of the filter case contain marking with the product code.

1 Type

FPT – Panel-type filter

2 Frame material, type of filtering material

FGPE – galvanized frame with polyester filtering material;

FPPE – plastic frame with polyester filtering material;

FSPE – stainless steel frame with polyester filtering material;

FGGF – galvanized frame with glass fibre filtering material;

FPGF – plastic frame with glass fibre filtering material;

FPGF – stainless steel frame with glass fibre filtering material

3 Purity class according to GOST R EN 779-2014

G3, G4, М5

4 Density of the filtering material

For polyester Р = 150, 200, 250, 400 gr/m2

For glass fibre P = 200, 250, 300 gr/m2

5 Filter dimensions

W – filter width – size of the smaller side of the filter, mm;

min 100 max 1000 mm.

H – filter height – size of the bigger side of the filter, mm;

min 100 max 1000 mm.

D – filter depth (frame);

min 15 max 100 mm. (standard size: 20; 25; 48; 96; 100 mm)

6 Fixing the filtering material.

RPS – mesh on the side of the air outlet, spokes on the side of the air inlet;

RD – mesh on both sides;

Marking example:

FPT - FGPE / G4 – 400 / 592 х 592 х 48 / RPS

Important!

Our company Research and Production Company MICROSISTEMA LLC manufacturers standard and non-standard ventilation filters of different designs and any dimensions at the request of the client.

Where and for what reasons PAF are used in plenum ventilation systems

Panel air filters (PAF) is a diverse line of products for the first cleaning step of intake (less often – exhaust) air.

Owing to the simplicity and reliability of design, safe assembly and disassembly, ability to withstand high mechanical and temperature load, PAF air filters are used in the ventilation devices for the premises of any purpose: household, commercial, production, etc.

Functions of panel filters for ventilation:

- Preliminary air cleaning (as a part of its preparation for feeding to fine filters) in multistep systems of filter-ventilation equipment of buildings and premises

- Basic (one-step) air cleaning in household and production premises with relatively low requirements to the purity level of the surrounding space

- Air cleaning in specialized production premises, such as chemical laboratories, coating booths, etc. Protection against dust, sand, abrasives, large aerosol particles and other macro-contaminants of air ducts, functional nodes of ventilation, heating and air-conditioning systems

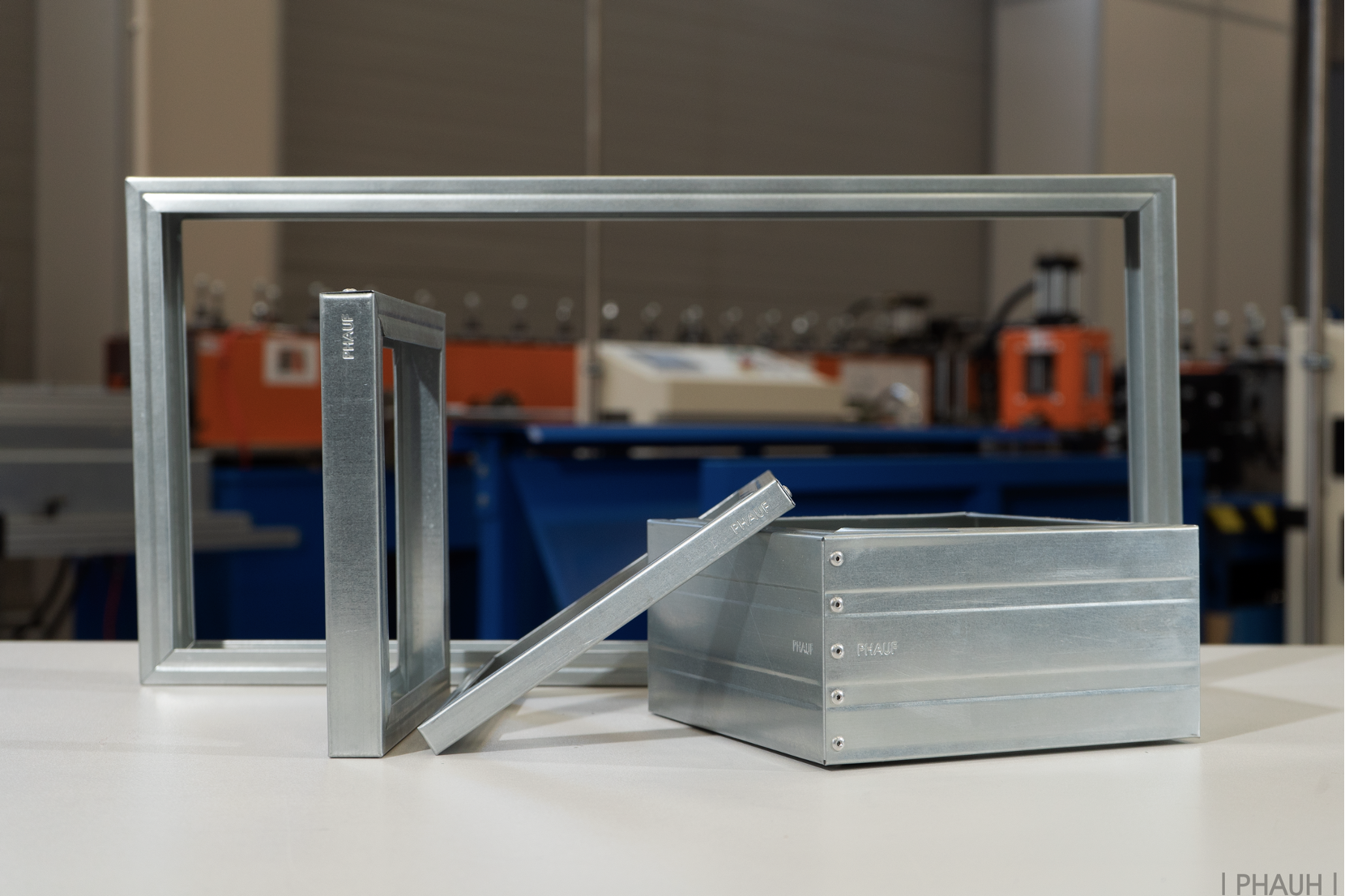

Design of panel air filters

Textured non-woven material is used for panel ventilation filters of the first cleaning step:

- High-quality chemical fibers (100% polyester, 100% polyether FilTek, PU foam)

- Glass fiber

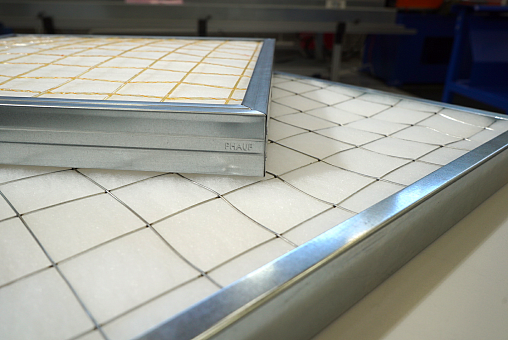

The filtering element of the product is represented by the cut filtering fabric laid over the support welded mesh made of reinforced or galvanized steel rods.

The wireframe ensures the reliability of fixing the filtering material in the product frame and increases the period of its operating life.

On the side of air flow inlet the filtering fabric is secured by steel diagonal rods (spokes) or a second wireframe.

The filter case is a rigid frame made of galvanized steel, stainless steel, fastened by riveted joints, or a plastic frame, fastened with rivets.

The dimensions (H x W x D) of the frame profile may be standard or determined based on the inputs of the individual customer who wishes to buy a non-standard PAF filter.

All filters for the ventilation equipment produced by Research and Production Company MICROSISTEMA LLC meet the requirements of the national industrial standards.

Purity classes

Panel type filters are intended for the rough (less often – medium) cleaning of the supply air.

Our company produces PAF with the following filtration classes (according to GOST R EN 779-2007):

- G3

- G4

- М5

Types of ventilation panel filters

High demand and flexibility in the use of panel-type filters have ensured the diversity of their modifications.

The brands are differentiated by the following specificities:

- Type of filtering material

- Application (for example, filters can be produced for round and square sections of air ducts)

- Method of fixing the filtering fabric in the framework profile

In the ventilation and air-conditioning systems, the panel filters of the following designs are used:

- Steel spokes at the inlet and a support mesh at the outlet of an air flow

- Wireframe on both sides of the filtering material

FAP technical characteristics

- Initial aerodynamic resistance (depending on the product brand): from 30 to 90 Pa

- Final aerodynamic resistance (depending on the product brand): from 130 to 250 Pa

- Initial dust content of the air: up to 3 mg/m3

- Operation at relative air humidity: up to 100%

Advantages of panel filters

- Light and robust design

- Easy safe assembly

- High DHC

- Low indicator of initial aerodynamic resistance

- Opportunity of filter generation by changing the filtering material (upon the achievement of final aerodynamic resistance, the contaminated fabric is retrieved from the frame and replaced with a new one)

- The used filter fabric is utilized as usual solid construction waste

- Fire safety (the materials are flame-resisting)

- Environmental safety

- Low price of the product

An important advantage of PAF filters is the combination of its low cost with the opportunity of multiple use

Panel Air Filter PAF

Panel air filters (PAF) are intended for the preliminary air cleaning in the ventilation systems and coating cameras. It is a compulsory element of ventilation systems providing for reliable protection from the particles of dust, fibre, paint, aerosol, etc. It offers the following advantages:

- even distribution of mud fractions;

- reliable fastening to the frame;

- low initial resistance;

- reliable protection: capture the particles of over 10 µm.

PAF Areas of Application

Panel filters are used for the rough preliminary air treatment and are installed as the first working point after the gate before the ventilator. In the single-step ventilation systems they may serve as the main air cleaning filter.

Panel-type filters have a broad range of application. They are used both in the premises of quite low requirements to the inlet air quality (schools, offices, warehouses, shopping centres, etc.), and in chemical / pharmaceutical laboratories, coating chambers, etc.

FTP Panel Filter Design

The panel filter PHAUF consists of:

- The profile made of galvanized iron, stainless steel, or plastic.

- Filtering material made of polyester / glass fibre of purity class (G3-М5).

- Supporting welded mesh of galvanized rods.

There are two types of design. The first includes meshes at both the inlet and the outlet. The second includes steel spokes at the inlet and a mesh at the outlet.

The price for panel filters depends on the sizes and filtering layer. Consequently, the higher are the filtrating properties of the material, the more expensive is the panel filter. Would you like to know the exact price? Contact us using the feedback form or by telephone: +7 (495) 108-43-97.

PAF Sizes

As our company has in-house production facilities, we can manufacture filters of any design and modification. Don’t hesitate to contact us in any manner convenient to you, and we will provide you with a free technical consultation on any matters.

The width of the profile, into which the filtering material is laid, usually amounts to 25, 48, 96, 100 mm. However, upon your request the specialists of the Research and Production Company MICROSISTEMA LLC will develop a filter of any purity class, size and design.

Purity Classes

Depending on the filtering effectiveness, three purity classes are identified: rough, fine, and ultra high (ULPA).

Rough cleaning panel filters (G1, G2, G3, G4) are able to retain the particles of over 10 μm. They include:

- large dust particles;

- insects;

- plant seeds;

- feathers and fluff;

- soot.

| Filtration | Class | Average dust holding capability (DHC) in respect of synthetic dust, % | Average effectiveness for the particles of 0.4 μm, % |

| rough cleaning | G1 | 50 ≤ Аm < 65 | - |

| G2 | 65 ≤ Аm < 80 | - | |

| G3 | 80 ≤ Аm < 90 | - | |

| G4 | 90 ≤ Аm | - | |

| medium cleaning | М5 | - | 40 ≤ Еm < 60 |

| М6 | - | 60 ≤ Еm < 80 | |

| fine cleaning | F7 | - | 80 ≤ Еm < 90 |

| F8 | - | 90 ≤ Еm < 95 | |

| F9 | - | 95 ≤ Еm |

Specifics of PAF Panel Filters’ Design

The specifics of panel type filters consist in the fact that the filtration ratio becomes higher during the accumulation of various contaminants. This happens due to the narrowing of the openings between the fibres. However, it should be noted that with time the openings narrow so much that the filtering material will stop providing for the necessary throughput capacity and will require replacement.

Methods of Tracking PAF Contamination

Panel filters ensure the establishment of optimal and safe microclimate in the premises for various purposes. Timely tracking of the degree of contamination prevents accelerated equipment wear and reduces the frequency of filter replacement.

Methods of tracking the filters’ clogging:

| Tracking the contamination level | Description |

| Visual | This method contemplates periodic inspection of the filtering layer for contaminants. |

| Automated | More precise method of contamination level control. Alert to the filter replacement is provided by the gas sensors, metres, pressure gauges. |

Requirements to Replacement Periods

The ventilation effectiveness directly depends on the degree of the filter contamination. To avoid damage to the equipment and internal finish of the premises, it is necessary to strictly comply with the manufacturer’s recommendations regarding the replacement timeframe.

The factors which impact the speed of contamination include:

- number of stories;

- seasonal nature and climatic specifics;

- presence of trees nearby, and pollen;

- general gas pollution.

A layer of dust and grease materially reduces the throughput capacity of the filtering layer. Besides, the dismantling and cleaning of ventilation units takes quite a lot of time and effort. It is recommended not to breach the established timeframe: once a month in summer and once in 2-3 months in winter.